Classification of the Outdoor Circuit Breakers

Outdoor Circuit breakers can be classified using different criteria namely:

- The intended voltage application

- The location of installation

- Their external design characteristics,

- The method and the medium used to interrupt the current

The voltage class

The classification of outdoor circuit breakers by their voltage class will be a logistical start. This is the voltage level at which the breakers are intended to be used. This first broad classification divides the classification into two categories. They are,

- Low voltage circuit breakers which are rated at voltages 1000 V a.c. or 1500 V d.c.

- High voltage breakers, which are obviously rated at voltages more than the values stated for low voltage breakers

The high voltage outdoor circuit breakers are future divided as breakers rated at 132 kV and above and those rated 72.5 kV and below. They are future grouped as transmission class or medium voltage class circuit breakers. This classification is based on the IEC-56 and 56 and IS the Indian standards.

Types of installation

The high voltage breakers can be used for Indoor or Outdoor Installations. The indoor circuit breakers are the designs, which are meant to be used inside buildings or inside weather-resistant enclosures. Breakers ranging from 3.6 to 36 K.V. are grouped as the medium voltage as per the IEC 56 and IS standards.

Types of External design

Form the physical structure of the designs, the outdoor circuit breakers are classified as a live tank and Dead tank breakers. The live tank breakers are those, in which the switching device whose vessel (s) the potentials are kept above ground level. Whereas in the case of Dead tank breakers the switching device’s vessel (s) are at ground potential.

Types of outdoor circuit breaker

The outdoor circuit breakers have been classified depending on the medium in which the arc burns and mechanism of arc control uses. They are

-

- Air circuit breakers (ACB)

- Oil circuit breakers

- Air Blast circuit breakers

- Vacuum circuit breakers and

- SF6 circuit breakers

1. Air Circuit Breaker (ACB)

Air circuit breakers quench the arc by mainly lengthening it; this is accomplished by pushing the arc into arc chutes. The arc chutes are provided with splitter plates, which tend to break up the arc and lengthen it while at the same time the plates cause cooling and de-ionization to the point when the arc chutes take place by its own electromagnetic force and by thermal action. Such devices are useful in low voltage applications. ACB with current limiting properties have enhanced their breaking capacity up to 100 kA in the low voltage range.

2. Oil Circuit Breaker (OCB)

The contacts of the oil circuit breakers were parted in the oil bath and the general movement of the oil, the cooling effect of the hydrogen created from the oil by the arc, arc the distance which separated the contacts, were the factors that cooled the arc path and created the dielectric strength needed to interrupt the relatively small fault currents in the earlier days of power distribution. As fault current increased, the increase in pressure due to vaporization of the oil by the short circuit current increased, the increase in pressure due to vaporization of the oil by the short circuit current increased the de-ionising properties of the hydrogen bubble surrounding the arc path and increased its dielectric strength, thus preserving the breaking capacity of this device.

Oil breakers came in two varieties namely bulk oil (OBCB) and minimum oil circuit breaker (MOCB). Due to the development of better arc control devices, the oil in the BOCB design was progressively reduced to result in the latter type of oil breakers. Oil circuit breaker has been designed from 11 kV, O.5GVA breaking capacity with one or two interrupters per phase up to 765 KV. 545 GVA capacity with ten breakers/ phase.

- Development of Modern Oil-less- Circuit breakers

The oil is no doubt has the good dielectric strength and insulating properties, but it is highly inflammable. Also, it is slower in operation and takes about 20 cycles for arc quenching. So, in the event, the breaker fails to quench. So, in the event the breaker fails to quench the arc, it is liable for fire hazards. This lead to the development of newer, fasting oil fewer outdoor circuit breakers which have short arc quenching time. The two newer technologies are the Air blast circuit breaker, Vacuum, and Sulpher hexafluoride circuit breaker.

3. Air Blast Circuit Breaker (ABCB)

Due to the continued increase in the fault levels, although the handling of these faults levels is not impossible in oil breaker. They would, however, lose the simplicity associated with them. The air blast circuit breaker in which the arc quenching takes place because of the flow of high-velocity air, scores over the oil breaker in the various aspects of fault clearing like

-

-

- high-speed operation

- Ability to withstand frequent switching

- Facility of high-speed re-closure

- Comparatively less maintenance

-

The variation of arching time is not much when it interrupts the small line charging current, magnetizing current of transformers or high short-circuit currents. Repeated switching can be performed by the air blast circuit breaker, as there is no carbonization of the contact surfaces. Care has to be taken with such breakers that the air (clean and dry) pressure to be maintained for frequent switching duties. While switching small currents, the problem of current chopping followed by the dangerous over voltages can be encountered.

In the current years, air blast outdoor circuit breakers are available having half a cycle breaking time at power frequency. They are used for a special application like for the High power laboratories worldwide.

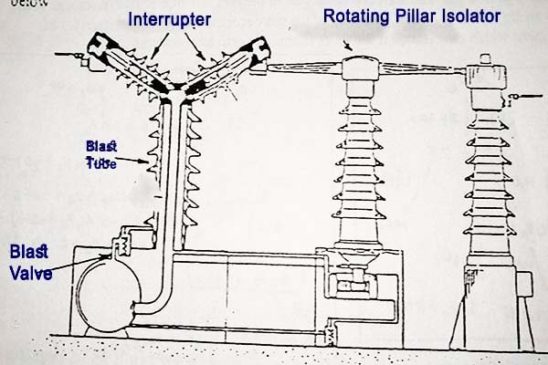

As it’s name suggestions an air blast outdoor circuit breaker operates by the use of a high velocity blast of air which literally blows the arc out. A typical air blast circuit breaker shown in below figure

The three main components are the blast tube, the interrupters and the blast value. In early designs which are still in use the contacts were held closed by means of a spring as shown in figure below

4. Vacuum Circuit Breaker

In this type of breaker, the arc bums in the metal vapor generated by arc when the contacts part. This is also called the metal vapor arc. Due to vacuum, this type of interrupter can have an extremely high rate of recovery of dielectric strength, which makes it a natural choice for re-strike free performance during capacitor switching at high voltage.

Only after the year 1960, this technology reached a point at which vacuum interrupters were capable of interrupting short circuit currents reliably. The manufacturing of VCBs requires a sophisticated technique and the materials processing makes it very it very expensive. The vacuum breaker development for 132 KV, 3500 MVA. 1200 A with eight breakers per pole, has taken place as early as 1967. However, vacuum interrupters are popular in the medium voltage range of 3.3 KV to 36 kV (both for outdoor circuit breakers and contactors).

The vacuum breakers are maintenance free, non-flammable; require relatively less mechanical energy to operate them. They have a salient operation. The dielectric recovery rate is faster.

5. SF6 circuit breakers

A breaker during which SF6 besieged gas is employed to extinguish the arc is named SF6 circuit breaker. SF6 (sulphur hexafluoride) gas has wonderful nonconductor, arc termination, chemical and alternative physical properties that have evidenced its superiority over alternative arc termination mediums like oil or air. The SF6 breaker is especially divided into 3 varieties

- Non-puffer piston breaker

- Single- puffer piston breaker.

- Double-puffer piston breaker.

The breaker that used air Associate in Nursingd oil as an insulating medium, their arc extinction force builds up was comparatively slow when the movement of contact separation. within the case of high voltage circuit breakers fast arc extinction properties area unit used that need less time for fast recovery, voltage builds up. SF6 circuit breakers have smart properties during this regards compared to grease or air circuit breakers. thus in high voltage up to 760 kilovolt, SF6 circuit breakers is employed.